The right industrial cooling machine for your needs.

HYFRA offers you a wide range of powerful air- and water-cooled chiller units with multiple equipment options that can be customized to satisfy your needs. Thanks to sector-leading HYFRA microchannel technology, our chiller solutions are highly efficient and deliver significant energy savings. And they use up to 60% less refrigerant. HYFRA cooling machines are also very compact: outputs of up to 28 kW are possible on bases of only 0.5 m², up to 80 kW on 1 m² and up to 160 kW on only 2 m². This results in significant flexibility advantages when planning production area layouts and a productivity boost as well.

The right chiller for your application.

The reliable cooling of liquids is an indispensable function in many industrial processes. Liquid chillers are often utilized to cool lubricants for metalworking applications, provide chilled fluid to tooling in plastics processing, and to dissipate the heat generated by lasers.

How are chillers being used in industrial process cooling?

The theory behind industrial cooling circuits is generally well understood: A cooling medium absorbs heat from a process and then needs to transfer that heat out of the system via a combination of refrigeration and/or heat exchangers. This coolant then returns to the heat source and the cycle starts again. Typical cooling media include: Demineralized water, water-glycol mixtures, water-based emulsions, and oil-based emulsions.

Which cooling medium is used where?

Demineralized water is well suited for cooling components and machines. Server racks, frequency converters, and other types of electronic equipment, for example, are often cooled with demineralized water. However, because this cooling medium is highly corrosive, all cooling lines must be made of stainless steel or other non-corrosive materials. Water-glycol mixtures enable the rapid removal of process heat. They are used, for example, for cooling milling spindles. Water-based emulsions are also frequently used to cool spindles and other machine components. Water-based emulsions have a heat capacity that is somewhat lower than that of water-glycol mixtures. As compared with demineralized water, a positive for systems with water-based mixtures/emulsions is that the piping does not require any special corrosion precautions. Oil-based emulsions are sometimes referred to as “cutting oils” and are primarily used as a lubricant in the interface between the chips and a machine tool’s cutting edge. The oil helps to reduce friction and aides in chip flow away from the cutting surface. Cutting oils are also employed as a cooling agent to remove any process-generated heat. The lubrication and cooling of the process can improve the surface finish of machined work. The use of oil emulsions requires pumps that can handle such highly viscous media.

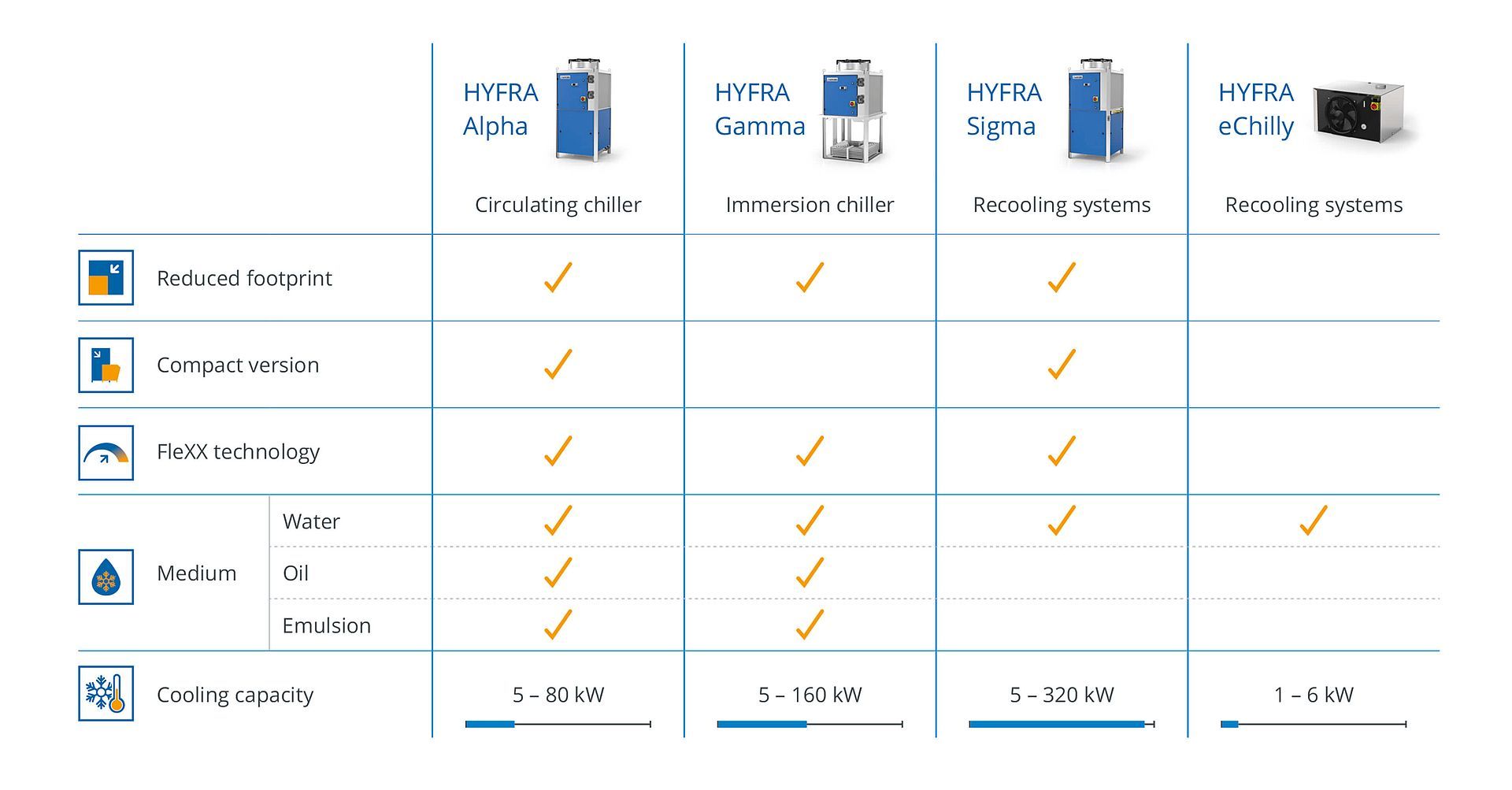

Proven technology from HYFRA in four designs

For liquid cooling HYFRA provides systems with capacities up to 320 kW (nearly 100 tons) cooling capacity. Depending on the concept, the HYFRA machines have different application focuses. Four series are available:

- HYFRA Alpha/Alpha c: Closed loop recooling

- HYFRA Gamma: Immersion (drop-in) cooler

- HYFRA Sigma/Sigma c: Recooling with integral tank

- HYFRA eChilly: Compact unit for recooling with tank

The HYFRA Alpha series comprises proven coolers in continuous flow technology. They are used for filtration, especially for cooling lubricants in machine circuits. The HYFRA Alpha is suitable for use for both water and oil-based media or any emulsion. Depending on the capacity, the Alpha units have a floor area of 0.5 m2 for up to 28 kW (8 tons) or a footprint of 1.0 m2 for sizes up to 80 kW (23 tons). There is also the super-compact Alpha c with capacities up to 16 kW (4.5 tons). These machines are space efficient utilizing only 0.5 m2 of floor space while at the same time reducing the standard chiller height by 40 %.

The HYFRA Gamma are powerful immersion (drop-in style) coolers for installation in both oil and water-based systems. They achieve cooling capacities from 5 to 160 kW (1.5 to 45 tons). The footprint is 0.5 m2 for cooling capacities up to 28 kW (8 tons) and 1.0 m2 for more powerful systems. They perform cooling via an evaporator coil that is placed directly in the customer’s system - typically immersed in a tank. A powerful stirrer is included to ensure that the cooled medium is agitated and well-mixed.

Chillers for cooling water-based fluids for machines and processes

Units of the HYFRA Sigma series achieve cooling capacities from 5 to 320 kW (1.5 to 100 tons). Their focus is the re-cooling of water-based fluids, for example in laser and machine tools. Due to the relatively small amount of refrigerant in this unit, the annual leak test is not necessary. Numerous options allow the HYFRA Sigma to be optimized for the application. The HYFRA Sigma c (compact) version has a footprint of only 0.5 m2 and is reduced in height.

The HYFRA eChilly is a compact chiller for capacities from 1 to 7 kW (0.3 to 2.0 tons). This plug-and-play unit is ideal for smaller applications such as welding machines, drilling stations, milling technology, and laboratory equipment.